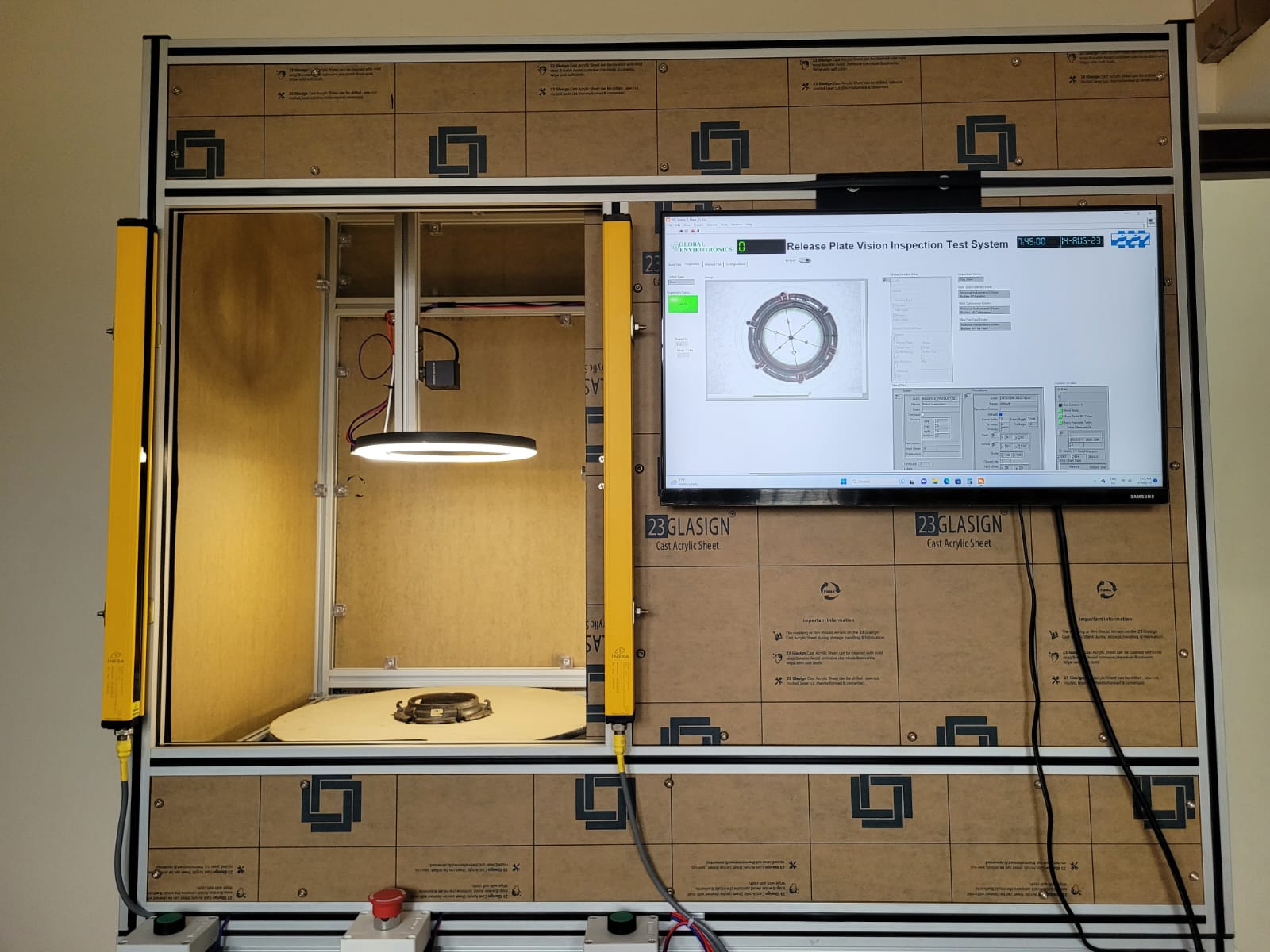

The Vision Inspection Darkroom Setup service involves the design and installation of a controlled environment, commonly referred to as a darkroom, for vision inspection systems. Vision inspection systems rely on precise imaging and analysis, and a darkroom provides the necessary conditions to minimize ambient light interference, ensuring accurate and reliable inspections. Key components and features of this service may include: Light Control: Designing the darkroom with light-tight materials and structures to prevent external light from entering the inspection area. Vision System Integration: Installing the vision inspection system within the darkroom, ensuring it is positioned optimally for capturing high-quality images without external light contamination. Lighting Systems: Implementing controlled lighting sources within the darkroom to illuminate the objects under inspection selectively. Workstation Design: Creating a functional workstation within the darkroom for operators to monitor and analyze the vision inspection results. Ventilation: Providing adequate ventilation to maintain a comfortable working environment for operators and prevent overheating of equipment. Safety Measures: Incorporating safety features, such as emergency lighting and exit signs, to ensure a secure environment for operators. Testing and Calibration: Conducting thorough testing and calibration of the vision inspection system within the darkroom setup to ensure optimal performance. This service is crucial for industries where vision inspection plays a critical role in quality control, such as manufacturing, electronics, and pharmaceuticals. The controlled darkroom environment enhances the accuracy and reliability of vision inspection systems, contributing to improved product quality and production efficiency.