Our Services

Key Expertise & Technical Proficiency – Powered by Weber360

Driving innovation at Weber360 through integrated expertise in electronics, embedded systems, automation, and advanced manufacturing.

- Engineering Design & Automation

- Embedded Systems & Software Development

- Advanced Manufacturing & Mechatronics

- Technical Leadership & Industrial Automation

Automated Test and Calibration Systems

Automated Test and Calibration Stand Design: Proficient in designing automated systems for precise testing and calibration of devices.

NI LabVIEW and TestStand: Hands-on experience in developing test automation and data acquisition systems using LabVIEW and TestStand.

Hardware Design and Development

PCB Design and Prototype Development: Expertise in designing complex PCBs and managing the end-to-end prototyping process, from schematic design to fabrication.

Schematic Design: Skilled in creating detailed and accurate circuit diagrams for electronics projects.

Electronic Component Soldering: Proficient in precision soldering for both SMD and through-hole components.

Electronics Design and Troubleshooting

Electronics Repair and Troubleshooting: In-depth expertise in diagnosing and repairing electronic systems.

Electronics Measurement Instruments: Proficient with oscilloscopes, multimeters, signal generators, etc.

Microcontroller and Embedded Electronics: Extensive experience in firmware and embedded system integration.

Sensors Design and Development: Skilled in sensor design for industrial and automation uses.

Embedded & IoT Development

Embedded Software Development: Proficient in ARM-based firmware, real-time systems, and hardware communication.

Communication Protocols: Expertise in Ethernet, CAN, PCI-e, SPI, I2C, RS-232/422/485, IEEE GPIB-488, and custom protocols.

IoT Solutions: Designing and implementing IoT systems with cloud integration.

GUI Development for Embedded Systems: Creating user-friendly interfaces for embedded platforms.

Desktop and Mobile Application Development

Desktop Application Development: Skilled in building scalable desktop apps for technical and industrial use cases.

Mobile App Development: Custom iOS and Android app development for device control and monitoring.

Programming & OS Proficiency

C/C++: Strong foundation in system-level and application programming.

Windows and Linux Systems: Experience in both OS platforms for embedded, testing, and development environments.

Microsoft Office: Effective use for documentation, analysis, and presentations.

Mechanical and Electronics Prototyping

Prototype Electronics/Mechatronics Project Implementation: Capable of translating ideas into functional prototypes.

Mechanical Spare Parts Manufacturing: Producing custom mechanical components using advanced machining techniques.

Manufacturing Tools & Operations

CNC Machine Operations and Maintenance: Skilled in operating, maintaining, and optimizing CNC machines.

3D Printing: In-depth knowledge of additive manufacturing, design, and material optimization.

Plastics Injection Molding Operations: Experienced in troubleshooting and operating molding machines.

CAD/CAM Design

CAD/CAM Software Expertise: Proficient in SolidWorks, Fusion 360, MasterCAM, Cut2D, and Aspire for design, simulation, and production.

Technical Leadership and Management

Team Management: Proven ability to lead multidisciplinary teams and ensure timely project delivery.

Project Implementation & Coordination: Skilled in managing timelines, quality, and cross-functional collaboration.

Industrial Robotics & Control Systems

Industrial Robotics Automation: Programming and deployment of robotic systems for manufacturing.

Robot Programming: Experience in developing and optimizing automated robotic programs.

Programmable Logic Controllers (PLCs): Skilled in PLC-based system design and automation.

Quality Control and System Automation: Ensuring process efficiency through advanced testing and QA practices.

General Technical Expertise

Electrical Systems: Proficient in wiring, troubleshooting, and electrical system integration.

Blueprint Reading: Skilled in interpreting and applying technical drawings in manufacturing and assembly.

- Embedded Firmware Development

- National Instruments

- PCB Design & Development

- IoT Product & Development

- Automated Test Systems

- Testand for Rental

- Hardware In Loop

- Industrial panel design

- Portable Test Systems

- Industrial Robotic Solution

Embedded Firmware Development

Embedded firmware development is a specialized branch of software engineering focused on designing and implementing low-level software that powers embedded systems. These systems are purpose-built computing units integrated into larger mechanical or electrical systems, commonly found in devices such as household appliances, medical equipment, industrial machines, and automotive electronics. Firmware in these systems acts as a bridge between the hardware and higher-level software, enabling devices to perform dedicated functions reliably and efficiently.

Developers in this domain require a deep understanding of hardware architecture, real-time operating systems (RTOS), and resource-constrained environments. They collaborate closely with hardware engineers to write optimized, stable code that fits within strict memory, processing, and power limitations. This involves working with low-level programming languages like C or assembly, as well as debugging tools and communication protocols. The role of embedded firmware development is critical to ensuring that embedded systems operate seamlessly, with high performance and long-term reliability.

Request for Quote

Industrial Automation with NI Platform

We help clients build customized automation systems by leveraging our predominant expertise in National Instruments (NI) hardware and software platforms. Our team specializes in designing, developing, and implementing reliable and scalable automation solutions that cater to a wide range of industries. From data acquisition and control systems to test and measurement setups, we utilize the full potential of NI tools such as LabVIEW, CompactRIO, PXI, and more to deliver high-performance automation systems tailored to specific client requirements.

In addition to NI-based solutions, we also offer seamless integration of third-party instruments and devices into the NI ecosystem. This ensures that clients can leverage their existing hardware investments while still benefiting from the robust capabilities of the NI platform. Whether it's communication via standard protocols, custom driver development, or multi-vendor system synchronization, our integration expertise enables smooth interoperability and enhances the overall efficiency and functionality of the automation system.

Request for Quote

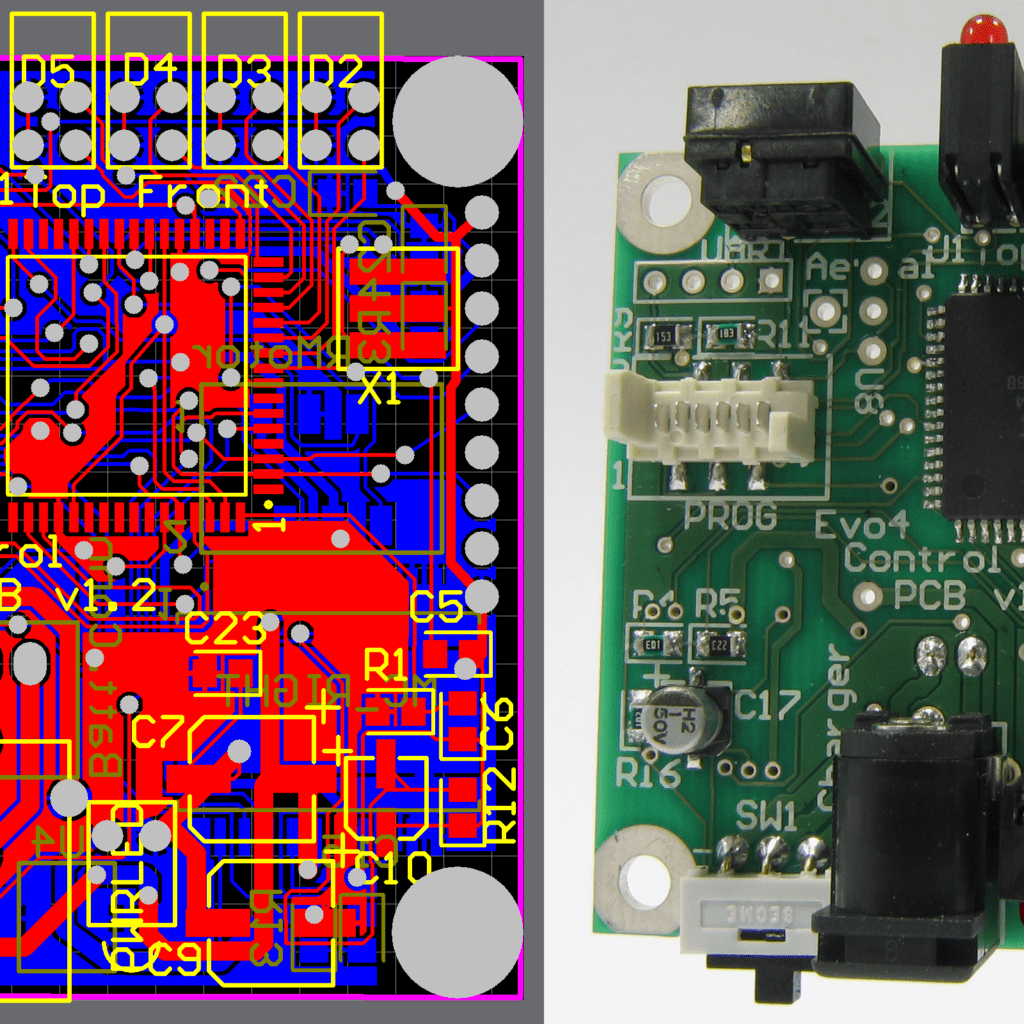

PCB Design & Development

PCB (Printed Circuit Board) design and development is a fundamental aspect of electronics engineering, focused on creating the physical platform that interconnects and supports electronic components. The design process combines electrical engineering principles with proficiency in specialized software tools such as Altium Designer, Eagle, or KiCad. Engineers carefully plan the placement and routing of components, taking into account critical factors like signal integrity, power distribution, electromagnetic interference, and thermal management. The objective is to achieve a compact, cost-effective, and functionally reliable layout that meets both electrical and mechanical requirements.

Once the PCB design is finalized, the development phase moves into manufacturing, which involves processes like copper layer etching, hole drilling, and applying solder mask and silkscreen layers. This step transforms the digital design into a physical board ready for component assembly and testing. PCB design and development directly impact the performance, durability, and size of electronic devices, making it a crucial stage in product development. As technology advances, PCB design continues to evolve—enabling the production of increasingly complex, multilayer, and miniaturized boards that power modern electronics across industries.

Request for Quote

IoT Product & Software development

IoT (Internet of Things) product and software development stands at the forefront of today’s digital transformation, driving innovation across industries. This field involves the creation of smart, interconnected devices capable of collecting, transmitting, and analyzing data over the internet. These devices—ranging from wearable health trackers and home automation systems to industrial machinery and environmental sensors—enable real-time monitoring, automation, and decision-making. The development process integrates both hardware and software, requiring engineers to design physical devices equipped with sensors and connectivity modules, alongside software that enables device communication, cloud integration, and user interface functionality.

A successful IoT solution demands a multidisciplinary approach, blending expertise in embedded systems, wireless communication, cloud computing, and data analytics. Developers must ensure reliable data transmission, low power consumption, and real-time responsiveness, all while maintaining scalability and interoperability. Security is a critical concern due to the connected nature of these systems, requiring robust encryption protocols, secure firmware updates, and data privacy safeguards. As the IoT landscape continues to expand, innovative product and software development will be essential to building smarter homes, cities, industries, and healthcare systems—ultimately shaping a more connected and efficient world.

Request for Quote

Automated Test systems

Automated test systems are vital components in both software and hardware quality assurance, designed to improve efficiency, consistency, and accuracy in the testing process. These systems rely on software-driven test scripts and predefined scenarios to automatically execute test cases, validate results, and generate reports. In software development, automated testing enables early detection of bugs, regressions, and performance bottlenecks, helping developers refine and stabilize code before deployment. It supports a wide range of testing methodologies, including unit testing, integration testing, and system testing, thus accelerating the development cycle while maintaining quality.

In hardware environments, automated test systems are used to evaluate the functionality, performance, and compliance of electronic components and assemblies. These systems can simulate real-world operating conditions, measure critical parameters, and ensure that products meet regulatory and safety standards. By reducing manual intervention, automated test systems offer improved repeatability, lower testing costs, and faster time-to-market. As products become more complex and time-to-market pressures increase, the role of automated testing continues to grow—ensuring reliable, high-quality output across industries such as automotive, aerospace, consumer electronics, and telecommunications.

Request for Quote

Testand for Rental

At Weber360.com, we specialize in providing a wide range of high-performance test stands for rent, designed to support all your testing requirements across diverse industries such as automotive, aerospace, electronics, research, and manufacturing. Whether you're working on prototype validation, endurance testing, performance benchmarking, or system diagnostics, our state-of-the-art test stands are calibrated, plug-and-play ready, and available with flexible rental terms — from short-term projects to long-term testing campaigns. With nationwide delivery, expert technical support, and customized solutions tailored to your application, Weber360 helps you save time, reduce costs, and accelerate development by giving you access to professional-grade equipment without the overhead of ownership.

Request for QuoteBroucher

Hardware in Loop Test Systems

Hardware-in-the-Loop (HIL) test systems play a critical role in the development and validation of embedded control systems, particularly in high-stakes industries like automotive, aerospace, and industrial automation. HIL testing involves connecting actual hardware components—such as electronic control units (ECUs), sensors, or actuators—to a real-time simulation environment that emulates the physical processes these components would encounter in the real world. This allows engineers to test how embedded systems behave under various operating conditions without the need for a fully assembled physical prototype, significantly enhancing the efficiency and safety of the testing process.

By simulating complex and dynamic scenarios—such as vehicle acceleration, braking, or fault conditions—HIL systems enable comprehensive validation of control algorithms, software logic, and hardware interactions. This approach helps identify potential design flaws, integration issues, or performance limitations early in the development cycle. The benefits of HIL testing include faster development timelines, reduced costs associated with physical prototyping, and improved system reliability and safety. As embedded systems continue to grow in complexity, especially with the rise of electric and autonomous vehicles, HIL test systems remain a cornerstone in ensuring robust and high-quality system performance.

Request for Quote

Industrial panel design and fabrications

Our solutions and services include, but are not limited to, comprehensive Panel Design and Fabrication, tailored to meet the specific needs of various industrial applications. We specialize in designing custom control panels that comply with industry standards, ensuring both functionality and safety. Our design process considers space optimization, component layout, wiring efficiency, and future scalability, delivering solutions that support reliable operation in demanding environments.

In addition to design, we offer Panel Manufacturing and Industrial Controls Support/Service. Our manufacturing capabilities ensure high-quality construction of control panels using certified components and precision assembly techniques. We also provide ongoing support and maintenance for industrial control systems, helping clients maintain optimal performance and minimize downtime. Whether it's troubleshooting, upgrades, or system integration, our team delivers responsive service to ensure your automation systems run smoothly and efficiently.

Request for Quote

Portable Test stations

Portable test stations are mobile and compact solutions designed to facilitate on-site testing across various industries and environments. These units integrate a range of essential testing instruments—such as power supplies, multimeters, oscilloscopes, signal generators, and data acquisition systems—into a single, easily transportable platform. This enables engineers and technicians to perform diagnostics, calibration, and validation tasks without the need for a full-scale lab setup. Ideal for field testing, maintenance, and remote operations, portable test stations combine functionality with flexibility, allowing for efficient and accurate testing wherever it's needed.

The adaptability of portable test stations makes them particularly valuable in manufacturing, aerospace, telecommunications, and service applications. They support rapid deployment and quick setup, helping teams troubleshoot and resolve issues on-site with minimal downtime. In addition to improving operational efficiency, these systems contribute to consistent quality control and streamlined workflow processes. With continuous advancements in miniaturization and wireless connectivity, modern portable test stations are becoming even more powerful and user-friendly—making them indispensable tools for ensuring the performance and reliability of electronic systems in dynamic and challenging environments.

Request for Quote

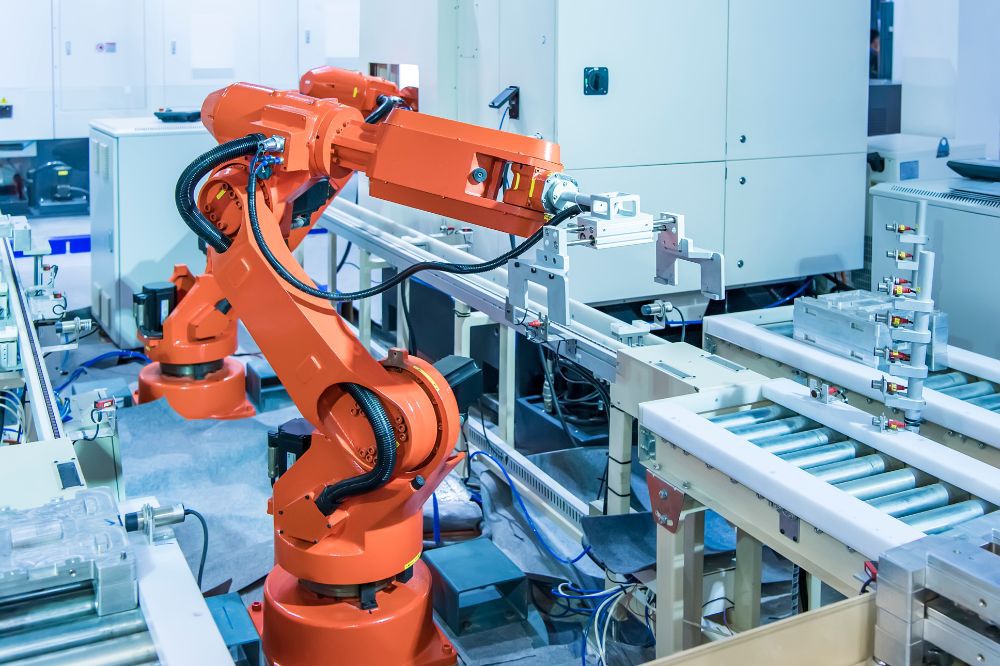

Industrial Robotic Solutions

Industrial robotic solutions are transforming the landscape of modern manufacturing by introducing high levels of automation, precision, and consistency. These systems are designed to take over repetitive, hazardous, or labor-intensive tasks, thereby increasing efficiency, reducing human error, and enhancing workplace safety. With the ability to operate continuously with minimal supervision, industrial robots significantly boost production output while maintaining high standards of quality. Applications span a wide range of functions, including assembly, packaging, material handling, welding, and inspection, making them indispensable in sectors like automotive, electronics, pharmaceuticals, and heavy machinery.

Equipped with sensors, vision systems, and advanced control algorithms, today’s industrial robots offer a high degree of flexibility and adaptability. They can be programmed to handle complex workflows and can even work collaboratively with human operators in what's known as collaborative robotics (cobots). This integration not only streamlines operations but also allows for quicker changeovers and customization in production lines. As technology continues to evolve, industrial robotic solutions are becoming more intelligent, accessible, and cost-effective—driving the next wave of innovation in smart manufacturing and Industry 4.0.

Request for Quote