In industrial automation, precise and reliable temperature monitoring is fundamental for safety, efficiency, and quality control. From chemical reactors and HVAC systems to food processing and cryogenic storage, accurate thermal data can make or break operations.

One of the most trusted temperature sensors in the field is the PT100 RTD (Resistance Temperature Detector). When paired with modern communication protocols like Modbus or CAN bus, these sensors become powerful building blocks of smart, networked temperature monitoring systems.

In this blog, we’ll explore the functionality, benefits, and real-world applications of PT100 Modbus and CAN Bus Monitor Devices—and how Weber360 supports their integration and development.

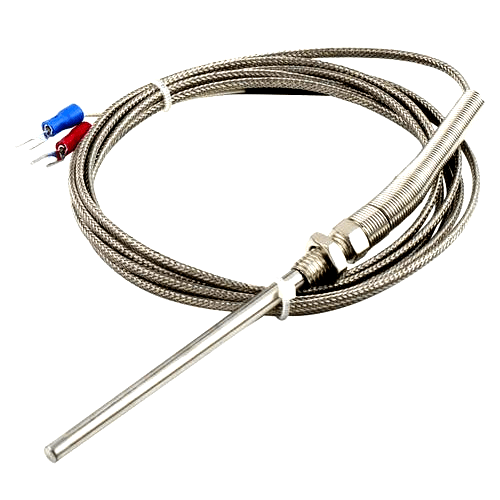

🔍 What is a PT100 Sensor?

The PT100 is a platinum resistance temperature detector where the resistance is exactly 100 ohms at 0°C. It is well known for:

• 🧊 High accuracy across a wide temperature range (-200°C to +850°C)

• 🔁 Excellent repeatability and long-term stability

• ⚙️ Linear response, especially within industrial temperature ranges

Its robust characteristics make it ideal for harsh and high-precision environments.

🔗 What is a PT100 Modbus or CAN Bus Monitor?

A PT100 Modbus or CAN bus monitor is a smart interface module that:

1. Reads analog resistance from PT100 sensors

2. Converts it into accurate temperature using a digital microcontroller

3. Transmits the data digitally over:

o Modbus RTU (RS485) or Modbus TCP (Ethernet)

o CAN bus (Controller Area Network) for real-time, fault-tolerant communication in distributed systems

These communication protocols allow you to easily integrate thermal sensing into PLCs, SCADA systems, vehicle networks, and remote monitoring solutions.

⚡ Key Features of PT100 Modbus/CAN Monitor Devices

✅ Multi-Protocol Communication

• Modbus RTU/TCP: Ideal for process plants, SCADA, and building automation

• CAN Bus: Perfect for automotive, robotics, and industrial equipment needing robust, real-time communication

✅ Multi-Channel Support

• Support for 1 to 8 PT100 inputs, with independent calibration and scaling

✅ High Accuracy ADC

• 16–24-bit resolution enables temperature readings accurate to ±0.1°C or better

✅ Wide Voltage Range

• Operates from 12–28V DC, supporting industrial power environments

✅ DIN Rail Mounting & IP-Rated Housings

• Rugged design for harsh operating conditions

✅ Advanced Diagnostics

• Over-temperature, broken sensor, and lead fault detection

• Configurable alarms over Modbus or CAN messages

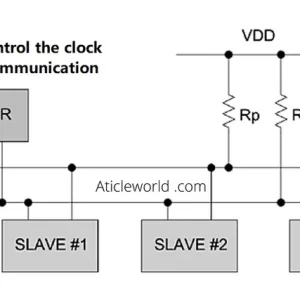

🔌 CAN Bus in Industrial and Embedded Systems

CAN bus is particularly important in applications like:

• 🚜 Agricultural and construction equipment

• 🏭 Industrial automation and robotics

• 🚚 Vehicle-based temperature control (reefers, LNG tankers)

• 🛰 Space and defense systems

• 🚆 Railway and marine systems

CAN bus enables fast, deterministic communication between multiple sensors and control units—perfect for environments requiring low-latency, noise-resistant data sharing.

🧪 Typical Use Cases

• ❄️ Cryogenic tank monitoring (LNG, LOX, LHe)

• 🏭 Factory automation and thermal process control

• 🧪 Laboratory and cleanroom environments

• 🚚 Fleet temperature logging (CAN bus)

• 🔬 Scientific research systems

• 🌐 IoT-based remote temperature logging

🛠️ Weber360 Support and Custom Development

At Weber360, we don’t just offer off-the-shelf PT100 monitoring devices—we partner with clients to develop custom solutions.

Our capabilities include:

• 🔧 Custom PCB & enclosure design

• 📡 Multi-protocol support (Modbus RTU, Modbus TCP, CAN bus, MQTT)

• 🖥️ Dashboard & cloud integration (local or remote)

• ⚙️ Sensor calibration and NIST-traceable testing

• 🔐 Secure firmware and OTA updates

Whether you need a rugged CAN-based sensor for a refrigerated truck fleet or a Modbus-enabled RTD monitor for cryogenic pipeline monitoring, Weber360 can design, prototype, and deliver complete solutions.

📦 Final Thoughts

As industrial systems evolve into smarter, connected platforms, temperature monitoring must follow. PT100 sensors combined with Modbus and CAN bus monitoring unlock scalable, accurate, and real-time thermal insights—whether in a lab, on the factory floor, or on the road.

Need help integrating PT100 sensors with Modbus or CAN bus? Want a custom monitoring solution built for your exact requirements?

📩 Contact the Weber360 engineering team today—we’re here to build it with you.