As the global energy industry rapidly evolves, the demand for precise, reliable, and real-time gas density measurement technologies is more critical than ever. Among the most challenging environments is the cryogenic domain, especially in liquefied natural gas (LNG) applications. To address these challenges, Weber360 is stepping forward with a mission: to design and develop next-generation gas density sensors tailored for cryogenic and harsh industrial environments.

Why Gas Density Matters

In natural gas and LNG systems, accurate density measurement is vital for:

• Fiscal and custody transfer

• Energy content calculation

• Process control and optimization

• Emission analysis

• Quality assurance

Density and its derivatives (specific gravity, calorific value, molecular weight) are critical parameters in achieving operational efficiency, regulatory compliance, and profitability. Existing solutions, such as the Thermo Scientific Sarasota FD900/ID900/PD900 series, offer robust performance in many applications—but the need for more compact, intelligent, and cost-effective alternatives remains high, especially as digital transformation accelerates across the energy sector.

Weber360’s Technological Approach

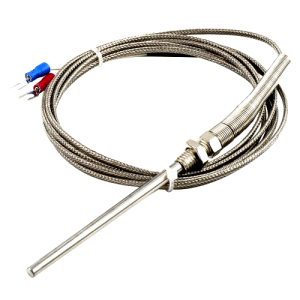

Weber360 envisions a compact, low-power cryogenic gas density sensor system that builds upon proven techniques such as:

• Vibrating cylinder (or spool) technology for accurate density measurements

• Integrated platinum RTDs (PT100) for real-time temperature compensation

• Pressure-immune designs where the sensor is fully immersed in the process fluid

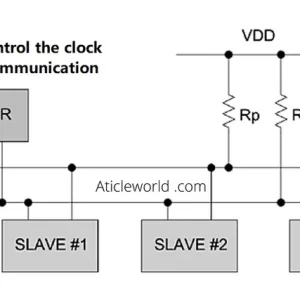

• Smart electronics with analog 4–20 mA and HART-compatible digital outputs

The new system will be designed to measure gas or LNG densities in the range of 0–1000 kg/m³and operate effectively down to -200°C, making it ideal for cryogenic environments such as LNG transfer lines, vapor recovery systems, or liquefaction plants.

Key Features Weber360 Plans to Integrate

1. True Inline Measurement: Minimal flow disturbance and direct insertion or pocket mounting for accurate, real-time monitoring.

2. Modular Electronics: Configurable outputs (frequency, analog, digital) to suit different automation systems.

3. AI-Enabled Calibration and Fault Detection: Onboard diagnostics to improve uptime and predictive maintenance.

4. Miniaturization and Lower Cost: Use of MEMS and advanced materials to reduce size and price, opening opportunities in distributed and mobile measurement systems.

Applications and Market Relevance

Weber360’s cryogenic gas density sensors will be suitable for a wide array of industries:

• LNG production and storage facilities

• Fuel gas metering for power generation

• Chemical process industries (ethylene, propane, etc.)

• Remote pipeline and tank monitoring systems

• Mobile and autonomous gas analysis platforms

With compliance in mind, sensors will be engineered to support ATEX, CSA, and IECExcertifications for hazardous environments.

A Strategic Leap in Sensor Technology

Leveraging its extensive experience in autonomous systems, sensor fusion, and embedded design, Weber360 is uniquely positioned to deliver a smart, rugged, and scalable solution for gas density measurement—pushing the boundaries of what is possible in cryogenic sensing.

As energy markets strive for efficiency, safety, and digital transformation, Weber360 is committed to pioneering solutions that enable a smarter and cleaner future.